The vast majority of our work on C'est la Vie since our haul out in June has gone into rigging. Being a sailboat our efforts to rejuvenate our primary source of propulsion seem appropriate, but we are not too proud to rely on our faithful Beta Marine when we need a little push. So it only seems fair that we devote some time (and money) to the engine as well.

Our new instrument panel and wiring harness are installed. Yes, this time the installation is well sealed with caulking. Mike from L&M marine took the lead on this project. I made some modifications to the engine room access below decks.

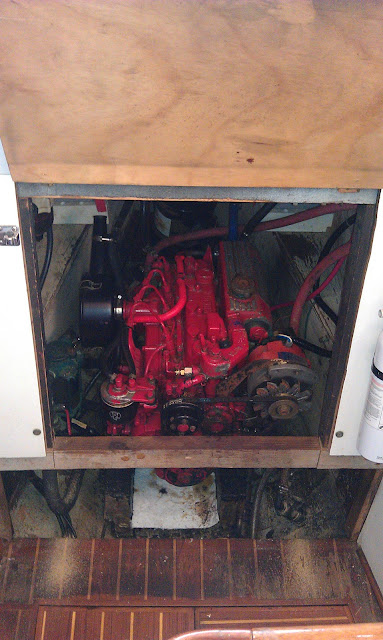

C'est la Vie's engine room access is located behind the companion way steps. I've spent many hours cursing the wooden cross brace while installing alternators, changing oil; replacing the starter, etc. My assumption was that a brace this obtrusive must be vitally important to the structural integrity of our vessel. Via discussions with Mike, a fellow M34 owner, and a closer inspection, I believe this brace can be removed.

Why have I not done that years ago? With the brace removed the panels on each side of the opening are more fragile. When the lower panel is screwed into place it serves with same function as the cross brace. To provide adequate purchase for screwing in the panel, I created new, enlarged braces on either side of the opening (lower, right below fire extinguisher in image above.)

The additional room in front of the engine allows us to relocate the raw water pump from the rear to the front of the engine (shiny, bronze object in center of image above.) This move will make changing impellers much easier.

P.S. Must admit I'm a bit embarrassed by the stained oil pad in the first image of the engine. I am compelled to state we do not have an oil leak, I keep this pad in place to catch any drips from changing or checking the oil. It is also a sure method of identifying if leaks occur. So we keep a clean oil pad under the engine. The stains on the pad in the image below are from work replacing the temprature gauge sensor and the oil pressure sensor.

Thursday, October 13, 2011

Wednesday, October 12, 2011

First coat of primer is on the mast step.

Despite the rumbling of distant thunder, I pushed my luck and proceed in applying the initial coat of primer to the mast step.

In anticipation for this winter's project of painting the decks with new non-skid, I expanded the area we will paint to include the hatch in the head. Future coats will include the area aft of the salon hatch, but I needed to fill some cracks and dings prior to painting the area.

In anticipation for this winter's project of painting the decks with new non-skid, I expanded the area we will paint to include the hatch in the head. Future coats will include the area aft of the salon hatch, but I needed to fill some cracks and dings prior to painting the area.

Tuesday, October 11, 2011

Unfortunate surprise in the lazurette leads to a new project.

Today's rains prevented any progress on the above deck projects. I did spend some time connecting the new stern anchor light and and re-connecting the wind generator in the electrical panel.

Mid afternoon, Mike from L&M Marine arrived with our Beta Marine order.

Have I mentioned that we ordered a new instrument panel and wiring harness from Beta Marine? A few days ago in an effort to better access the wires in the lazurette we slid aside our propane locker and were appalled at the rust & corrosion on the back side of the instruments. The entire housing for our oil pressure gauge was paper thin. I am amazed the ignition switch was still working with all the corrosion on the terminals.

I'm guessing the area took a soaking during last fall's rough five day crossing from Wilmington, NC to the Abacos.

When taking green water across the decks an occasional stream ran past the cockpit combing and down the back side of the cockpit near the main sheet traveler. This water likely found it's way to the backside of the instruments via an insufficient seal around the instrument panel.

Well the old panel is now history. Mike took the housing back to his shop to install the new panel.

When Mike removed the old panel there was no caulking around the housing. To be sure we will remedy this when the new panel is installed.

Like any good boat project this is growing larger by the minute. A new panel has new gauges. New gauges require new sending units on the engine. It seems the new gauges do not speak the same language as the old sending units. Well new sending units require a new wiring harness. Oh yes and while we are getting greasy lets replace and relocate the raw water pump. And so goes the creation of an new list of projects.

Mid afternoon, Mike from L&M Marine arrived with our Beta Marine order.

Have I mentioned that we ordered a new instrument panel and wiring harness from Beta Marine? A few days ago in an effort to better access the wires in the lazurette we slid aside our propane locker and were appalled at the rust & corrosion on the back side of the instruments. The entire housing for our oil pressure gauge was paper thin. I am amazed the ignition switch was still working with all the corrosion on the terminals.

I'm guessing the area took a soaking during last fall's rough five day crossing from Wilmington, NC to the Abacos.

When taking green water across the decks an occasional stream ran past the cockpit combing and down the back side of the cockpit near the main sheet traveler. This water likely found it's way to the backside of the instruments via an insufficient seal around the instrument panel.

Well the old panel is now history. Mike took the housing back to his shop to install the new panel.

When Mike removed the old panel there was no caulking around the housing. To be sure we will remedy this when the new panel is installed.

Like any good boat project this is growing larger by the minute. A new panel has new gauges. New gauges require new sending units on the engine. It seems the new gauges do not speak the same language as the old sending units. Well new sending units require a new wiring harness. Oh yes and while we are getting greasy lets replace and relocate the raw water pump. And so goes the creation of an new list of projects.

Monday, October 10, 2011

Before the rains began to fall

With rain forecast to begin falling by late afternoon, we worked to tick off as many outside projects as possible. We started the day by re-installing the dodger and bimini. These will better allow us to continue working on interior projects during the rainy days. Both the dodger and bimini were removed in early summer to limit UV damage and reduce our windage during hurricane season. While the dodger was off the boat, Tony at Beaufort Canvas replaced the leather wrap along the top, aft edge. This part of the dodger frequently serves as a hand hold while in the cockpit. Over the course of 4 years we had worn through the original leather wrap.

Once the bimini and dodger were re-installed, I went back to work sanding and fairing the mast step. Anne focused on pulling the new coax wiring for the AM/FM antenna and for the new anchor light, both mounted on the stern wind generator post, to C'est la Vie's electrical panel.

I completed fairing the mast step just as the rain drops began to patter on the deck.

By this time Anne had completed running the wires and moved on to assembling the wind generator blades.

Rain is forecast to continue for the next 36 to 48 hours. Looks like tomorrow's efforts will be limited to interior projects.

Once the bimini and dodger were re-installed, I went back to work sanding and fairing the mast step. Anne focused on pulling the new coax wiring for the AM/FM antenna and for the new anchor light, both mounted on the stern wind generator post, to C'est la Vie's electrical panel.

I completed fairing the mast step just as the rain drops began to patter on the deck.

By this time Anne had completed running the wires and moved on to assembling the wind generator blades.

Rain is forecast to continue for the next 36 to 48 hours. Looks like tomorrow's efforts will be limited to interior projects.

Sunday, October 9, 2011

Arts and Crafts day on C'est la Vie - part 1

With all the standing rigging down the time is right to tick off a long time resident of the projects list - rebuild the chain plate deck fittings. I'm unsure of the technical name for these things, but they serve to keep water from intruding into the cabin where the chain plates pass through the deck. They perform this task in two ways. First, they are raised so thin sheets of water running across the deck will pass round the structure. Secondly they have a recessed reservoir that when filled with caulk and compressed by a metal top plate forms a water tight seal around the metal chain plate. C'est la Vie has four such fittings on her deck. The aft fittings are doubles and accommodate the cap and aft lower shrouds.

Visible in the image above is a green outline of what I envision the for the shape of the finished product. The forward fitting is a single chain plate that serves the lower, forward shroud.

In the images above the metal fittings are the chain plates. The yellow modeling clay is filling the reservoir and extends above the height that I plan to build up the new fittings. Surrounding the modeling clay are the eroding remnants of the original fittings.

At the the stage of the process pictured above, I have drilled out and refilled with epoxy the four screw holes used to tighten down the metal top plate. With these holes filled the next step was to create a mold for the new deck fitting. Modeling clay works well as a mold for epoxy, but how to create nice round ends and straight sides? I searched around the boat for a something that looked to be the appropriate radius.

Can't use the can, but the lid will do nicely.

I cut the plastic lid in half vertically for use as a guide, and then molded the clay around the lid.

Once the round ends were complete, I used a straight edge and a box cutter blade to clean up the sides of the mold.

Repeat this process on each of the four fittings and it is time to pour the epoxy. I used West System epoxy thickened to a consistency somewhere between honey and ketchup with high density filler.

Allow epoxy to fully set... see part 2

Visible in the image above is a green outline of what I envision the for the shape of the finished product. The forward fitting is a single chain plate that serves the lower, forward shroud.

In the images above the metal fittings are the chain plates. The yellow modeling clay is filling the reservoir and extends above the height that I plan to build up the new fittings. Surrounding the modeling clay are the eroding remnants of the original fittings.

At the the stage of the process pictured above, I have drilled out and refilled with epoxy the four screw holes used to tighten down the metal top plate. With these holes filled the next step was to create a mold for the new deck fitting. Modeling clay works well as a mold for epoxy, but how to create nice round ends and straight sides? I searched around the boat for a something that looked to be the appropriate radius.

Can't use the can, but the lid will do nicely.

I cut the plastic lid in half vertically for use as a guide, and then molded the clay around the lid.

Once the round ends were complete, I used a straight edge and a box cutter blade to clean up the sides of the mold.

Repeat this process on each of the four fittings and it is time to pour the epoxy. I used West System epoxy thickened to a consistency somewhere between honey and ketchup with high density filler.

Allow epoxy to fully set... see part 2

Arts and Crafts day on C'est la Vie - part 2

The battery powered Dremel with a rough sanding drum saved a great deal of time and effort when addressing the interior edges of the reservoir. Initial sanding complete it is time to add the fillets (rounded edges) and remedy any gaps in the initial round of epoxy.

I refilled the reservoirs with model clay and re-taped the surrounding area before mixing up another round of epoxy. This time around I used a fairing filler to thicken the epoxy to a consistency similar to petroleum jelly. The fairing fillers are easier to sand down and this application is more about cosmetics than structure.

No clay molds on this application. The epoxy was added to the fitting using a stir stick and a 3" spreader. Before the epoxy fully set, I used a razor blade to cut through the skin across the top of the area filled with modeling clay. Once cured I removed the clay and tested the height of the new fitting by inserting the chain plate and attaching the turnbuckles. It is a very important test the fitting before continuing on to painting. I found that I had raised both forward fittings too much. The forward fittings did not allow enough clearance for the shoulders of the turnbuckle. I removed to excess material from the top of the fitting, approx 3/32", using an orbital sander armed with 80 grit paper. The aft fittings did not require any material removal.

Another round of sanding with 80 grit paper followed by a round with 120 grit paper preceeded the application of primer.

Subscribe to:

Comments (Atom)